Supply Chain Management (SCM)

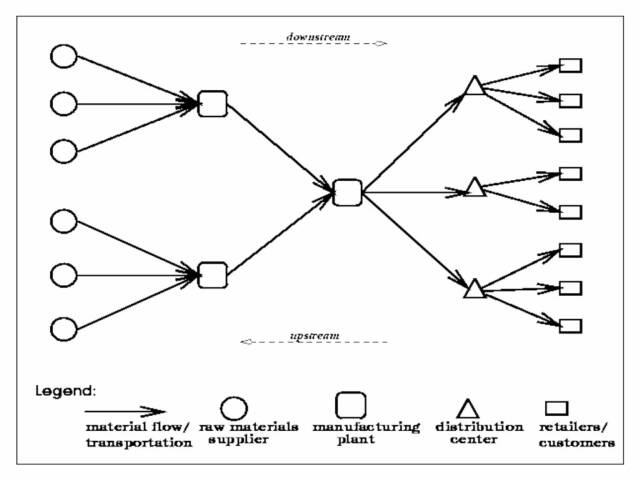

Supply Chain Management involves the flow of materials, information, and finances as they move in a level process from supplier, to manufacturer, to wholesaler, to retailer, and finally to the consumer. SCM involves coordinating and integrating these flows among all companies involved. Each level of the supply chain is described as a “tier.” There can be several tiers beneath the final supplier.

In the example given, materials flow downstream through a manufacturing level (tier) transforming the raw materials, which are the components or parts. These are assembled on the next level to form products. The products are shipped to distribution centers, and from there on to retailers and customers.

Logistics Management is the part of SCM that efficiently plans, implements, and controls the delivery and storage of goods and services.

Supply chain management flows can be divided into three main flows:

- Product flow - which is the movement of goods from a supplier to a customer, as well as any customer returns or service needs.

- Information flow - which involves transmitting orders and updating the status of delivery.

- Finances flow - which consists of credit terms, payment schedules, and consignment and title ownership arrangements.

There are three levels of decisions associated with SCM:

- Strategic - Long-term decisions related to location, production, inventory, and transportation.

- Tactical - Medium-term decisions such as weekly demand forecasts, distribution and transportation planning, production planning, and materials requirement planning.

- Operational - Day-to-Day decisions as part of normal managerial duties.

The following five steps are typical purchase procedures:

- Specify the amount needed.

- Determine the supplier based on pricing comparisons.

- Negotiate the price as well as payment terms, warranty, and timed cost reductions. Dealing with supplies or commodities depends on their availability, price and quality.

- Purchase the supplies.

- Delivery and inspection of the supplies.

Focusing on certain areas within the supply chain can reduce costs. There might be times when buying in bulk is cost effective. JIT, FIFO and LIFO will be discussed in the following Inventory Management section of this lesson.

Manufacturing Resource Planning (MRP) as part of SCM can help plan and determine the supply needs and timelines for new manufacturing processes in order to predict product delivery schedules, and respond to changes in the market or product. It is a software based production planning and inventory control system used to manage manufacturing processes. The three major objectives of MRP are:

- Ensure materials and products are available for production and delivery to customers.

- Maintain the lowest possible level of inventory.

- Plan manufacturing activities, delivery schedules, and purchasing activities.

Sophisticated software systems with Web interfaces are competing with Web-based Application Service Providers (ASP) who provide SCM service for companies who rent their service. A number of major Web sites offer e-procurement marketplaces, which is the business-to-business purchase and sale of supplies and services over the Internet. Manufacturers can trade and even make auction bids with suppliers.

The five basic Supply Chain Management steps are:

- Plan – Strategic planning by developing a set of metrics to monitor the supply chain so that it is efficient, costs less, and delivers high quality and value to customers.

- Source – Choose the suppliers that will deliver the goods and services you need to create your product including pricing, delivery and payment. Also managing the inventory of goods and services you receive from suppliers, including receiving shipments, verifying them, transferring them to your manufacturing facilities, and authorizing supplier payments. This is all done while at the same time continuously monitoring the metrics for possible improvement.

- Make – Manufacture your product. Schedule the activities necessary for production, testing, packaging and preparation for delivery. Always measure quality levels, production output, and worker productivity.

- Deliver– Also known as logistics. Coordinate the receipt of orders from customers, develop a network of warehouses, pick carriers to get products to customers, and set up an invoicing system to receive payments. Shipping options can include:

-

- FOB (Free On Board) Factory Pricing where the buyer bears the shipping cost.

- Freight Absorption Pricing in which paying some of the transportation costs are in line with competitors.

- Uniformed Delivery Pricing in which a standard price is set no matter the location.

- Zone Pricing in which you charge different prices for different geographical locations.

- Return– Also known as RMA or Return Merchandise Authorization. A system for receiving defective and excess products back from customers, and supporting customers who have problems with delivered products.